CS, SS Tubes Manufacturers In India

- Home

- Tubes

Premium Tubes Manufacturer & Supplier in India

Emcor Engineering is a leading manufacturer and exporter of seamless tubes, offering a comprehensive range of services to meet customer needs. With a strong focus on customer satisfaction, we provide 24-hour service and optional next-day delivery. Our products undergo rigorous testing, including mechanical, supersonic, eddy current, hydrostatic, and chemical testing, ensuring high quality.

Our tubes are known for their high tensile strength, smooth internal finish, and hardness, making them ideal for various applications such as marine, power plants, pipelines, and more. We maintain a large stock for quick delivery and engage closely with customers to achieve the best results. Our range caters to diverse industrial sectors, including Oil & Gas, Power, Pharmaceuticals, Water Treatment, and more.

- Manufacturing Range:- 8 mm to 212mm

- Thickness : 0.8mm – 10mm – All Guage: 10 SWG/BWG to 22 SWG/ BWG

- Material Types:- Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel, Super Duplex Steel, Low-Temperature Carbon steel (LTCS), Copper and Nickel Monel, Inconel, Hastelloy, etc.

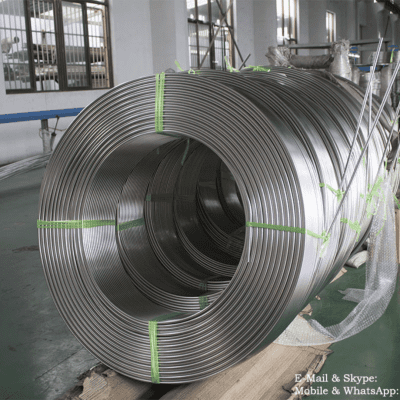

- Products: Round Tube, U Tube, Coil Tube etc.

Extensive Range of Tubes We Offer

We pride ourselves on offering a versatile assortment of tube types to meet diverse industrial needs:

Stainless Steel Tubes

Carbon Steel Tubes

Alloy & Specialty Metal Tubes

Seamless Tubes

Precision Tubes

What Sets Emcor Tubes Apart

Unlike generic tube suppliers, Emcor Engineering’s tubes are distinguished by:

Dimensional Precision & Tolerance Control — every tube is checked to ensure consistent wall thickness, diameter, and straightness.

Material Excellence — using high-grade materials (SS, alloy steel, etc.) for corrosion resistance, strength, and longevity.

Pressure & Thermal Endurance — designed to withstand high pressure, temperature extremes, and cyclic loads common in industrial environments.

Availability of Custom Solutions — we provide tubes cut, formed, or finished to client specifications, not just standard stock.

Key Industries & Applications

Our tubes find usage in:

Petrochemical & Chemical Processing

Power Generation & Boilers

Oil & Gas Infrastructure

Automotive & Machinery

Structural Frameworks

HVAC & Heat Exchangers

In every installation, we aim for minimal maintenance, reliable flow, and long service life.

Quality Assurance & Standards

We adhere to the strictest quality practices:

Material Certification & Traceability

Non-destructive Testing (NDT) such as ultrasonic tests, eddy current tests

Dimensional inspections and tolerances

Compliance with relevant standards

Routine sample testing under pressure, temperature, and fatigue cycles

These practices ensure each tube meets performance expectations in critical systems.

Partner with Emcor Engineering for Tubes

Whether you need standard stock tubes or custom-engineered solutions, Emcor Engineering has the experience and infrastructure to deliver. We operate with a commitment to timely supply, consistent quality, and technical collaboration.

Contact Us today to discuss your tube requirements.

To support your broader system needs, Emcor also offers:

A comprehensive range of tube fittings engineered for leak-free and robust connections

High-performance pipes designed for fluid transport under diverse conditions

This internal network ensures that your entire flow system, from tubing to connections to piping, is covered by trusted Emcor solutions.

FAQs on Tubes

Yes. Emcor Engineering supplies tubes in large quantities, while ensuring uniform quality and on-time delivery for major projects.

Yes. We offer technical guidance, installation assistance, and ongoing support to ensure seamless integration into your systems.

You can contact us via our website or speak directly with our sales team to get a custom quote tailored to your requirements.

We produce tubes using stainless steel, carbon steel, alloy steel, and specialty metals depending on operational demands.

Our tubes are used across petrochemical, power generation, oil & gas, automotive, and structural engineering sectors.

Absolutely. Emcor Engineering offers customization in length, diameter, wall thickness, and surface treatment to meet precise application demands.

Yes. All Emcor tubes are manufactured and tested to meet standards and applicable norms.

We use rigorous inspection methods (NDT, dimensional checks, material tests) and maintain full traceability from raw material sourcing to delivery.